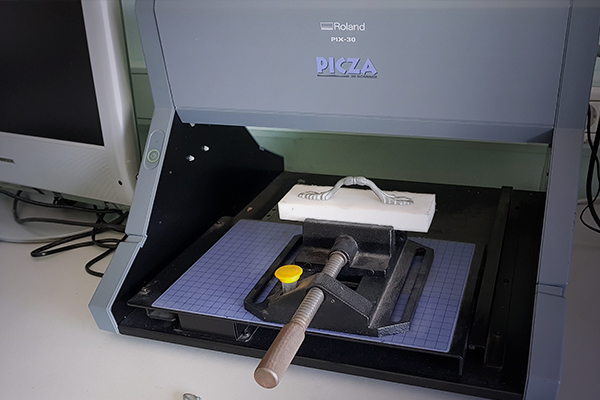

Contact and contactless technologies

Reverse Engineering

Reverse engineering is an industrial process where an existing product, whatsoever its nature, is analysed and recreated in order to obtain a 3D CAD model.

Reverse engineering can be achieved by using different technologies, typically divided into "contact measurement system" or "contactless" projection. In the first case, a mechanical arm moves on the piece and generates a point each time it touches it. In contactless technologies, a laser is projected onto the piece to generate the same points using reflection recognition techniques.

Used for:

- To detect unique “hand-made” pieces

- To recreate an object in case original documentation no longer is available

- To capture a design in 3D data

- To verify dimensional data

SCANNING RESULT

Scanning result, a cloud of data points, can be modified and converted in to STL file. STL file is ready to use for 3D rapid prototyping. More advanced approach is to create IGS or STP format file for transferring 3D model files into CAD.